A New Choice for Deep Fluoride Removal: ZONE Deep Fluoride Removal Balls, Safeguarding Drinking Water Health and Industrial Water Quality Safety

Update time: 25-11-25 Views: 101

Water is the source of life and a cornerstone of industrial production. Yet, excessive fluoride in natural water bodies and industrial wastewater has emerged as a silent threat—long-term consumption of fluoride-contaminated drinking water causes dental fluorosis and skeletal fluorosis, while unprocessed industrial fluoride-laden wastewater devastates soil ecosystems, pollutes groundwater, and endangers production safety in high-end sectors like photovoltaics and electronics. Amidst this challenge, the demand for efficient, safe, and long-lasting deep Fluoride Removal solutions has never been more urgent. As a 23-year veteran in the water treatment industry, ZONE introduces the ZONE-F-E01 Deep Fluoride Removal Balls—a game-changing innovation that redefines fluoride removal efficiency and reliability.

I. Core Advantages of ZONE Deep Fluoride Removal Balls: 3 Key Breakthroughs Over Traditional Media

What sets ZONE Deep Fluoride Removal Balls apart from conventional alternatives? Three core advantages address the most pressing pain points of fluoride removal:

1. Ultra-High Fluoride Removal Capacity

With a fluoride removal capacity 6-8 times higher than traditional activated alumina and carbon-based apatite, ZONE’s filter media can treat significantly more fluoride-containing water under the same dosage. This means fewer media replacements, reduced downtime, and lower operational costs—especially critical for high-flow industrial applications or regions with severe fluoride contamination.

2. Zero Secondary Pollution Risk

Safety is non-negotiable, whether for drinking water or industrial use. ZONE Deep Fluoride Removal Balls leach no harmful ions during the purification process, ensuring effluent meets the strict fluoride limit (≤1.0mg/L) set by China’s Sanitary Standards for Drinking Water (GB 5749-2022) and the rigorous requirements of high-end industrial water (e.g., photovoltaic, electronics manufacturing).

3. Flexible & Versatile Application

Designed specifically for terminal deep fluoride removal, these balls seamlessly integrate with existing water treatment systems to further reduce fluoride concentrations, guaranteeing compliance. They perform reliably across complex water conditions, making them suitable for both civil/commercial drinking water purification and heavy-duty industrial wastewater treatment.

II. Technology Behind the Excellence: Material Innovation & Dual-Purification Mechanism

ZONE’s Deep Fluoride Removal Balls are the result of years of R&D, built on advanced "porous material modification technology" to deliver unmatched performance:

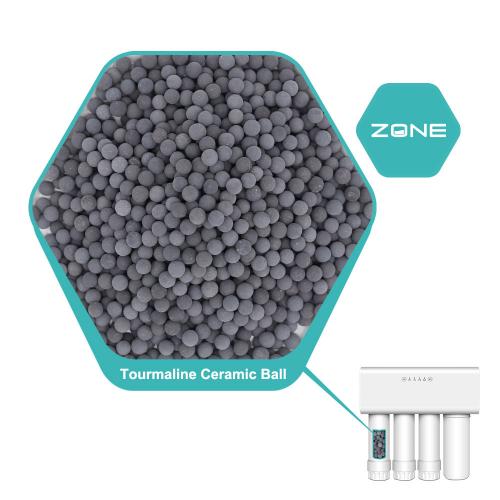

1. Material Innovation: Porous Composite Ceramic Structure

Unlike single-component traditional media, ZONE’s filter balls feature a porous, highly dispersed composite ceramic material. Their internal network of micropores and mesopores creates an enormous specific surface area—acting like a "microscopic adsorption warehouse" that provides countless sites for capturing fluoride ions. Additionally, the media surface is loaded with high-efficiency ion purification materials, enhancing selective adsorption of fluoride compounds for targeted removal.

2. Dual-Mechanism Purification: Adsorption + Ion Exchange

The balls achieve thorough fluoride removal through a synergistic combination of two processes:

- Physical Adsorption: The high specific surface area rapidly traps fluoride ions and fluoride compounds on the media surface, enabling initial purification.

- Chemical Ion Exchange: Active components on the media undergo specific ion exchange with fluoride ions, converting them into stable, water-insoluble fluorine compounds. This eliminates the risk of secondary leaching and ensures long-lasting purification effects.

This dual mechanism resolves the limitations of traditional media—avoiding rapid saturation and secondary pollution while delivering consistent, efficient results.

III. Rigorous Testing & Proven Performance: Data You Can Trust

ZONE’s commitment to quality is backed by precise product parameters and rigorous laboratory testing, ensuring reliability in real-world applications:

Product Parameters

Specific Indicators

Product Model

ZONE-F-E01

Specifications (Diameter)

1.0-1.5mm

Bulk Density

1.1g/cm³

Material

Composite Ceramic

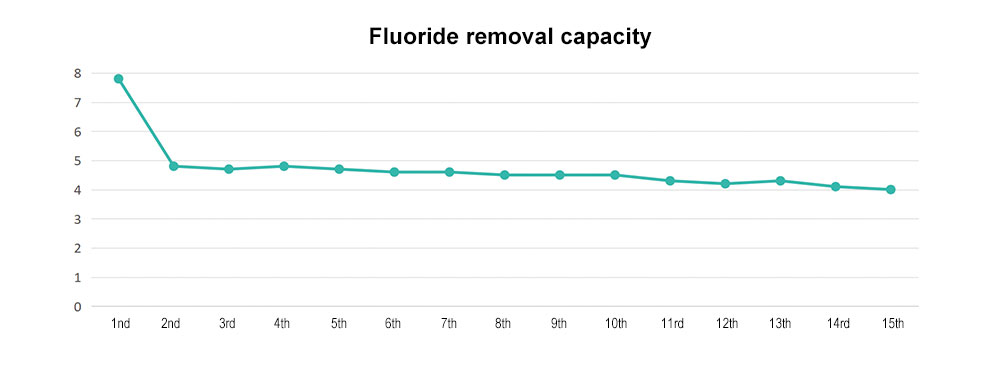

Laboratory Performance Test (Simulated Real-World Scenarios)

- Test Conditions: Raw water fluoride content = 7.8ppm (far exceeding safe limits), pH adjusted to 6-6.5, flow rate = 90ml/h (simulating 3m³ of water treated per hour per ton of filter media).

- Test Results: Continuous 24/7 water flow until effluent fluoride exceeded 1.0mg/L. ZONE’s media treated significantly more water than traditional alternatives, with stable effluent quality throughout the test period—proving its durability and efficiency.

IV. Why Traditional Fluoride Removal Media Fall Short

To fully appreciate ZONE’s innovation, it’s critical to understand the long-standing flaws of conventional Fluoride Removal Media:

1. Low Capacity & Easy Saturation: Activated alumina, the most common option, has limited adsorption capacity. It saturates quickly in high-fluoride water (e.g., industrial wastewater), requiring frequent regeneration and increasing maintenance costs.

2. Secondary Pollution Risks: Carbon-based apatite media may leach trace harmful ions, making them unsuitable for drinking water or high-precision industrial applications.

ZONE’s Deep Fluoride Removal Balls directly address these pain points, offering a superior alternative for modern water treatment needs.

V. Full-Scenario Applications: From Drinking Water to Industrial Wastewater

ZONE’s Deep Fluoride Removal Balls adapt to diverse purification needs, covering two core sectors:

1. Civil/Commercial Drinking Water Terminal Purification

Ideal for terminal filter cartridges in household water purifiers and commercial direct-drinking water systems. It solves groundwater fluoride excess in specific regions, delivering "last-mile" deep purification to protect public health.

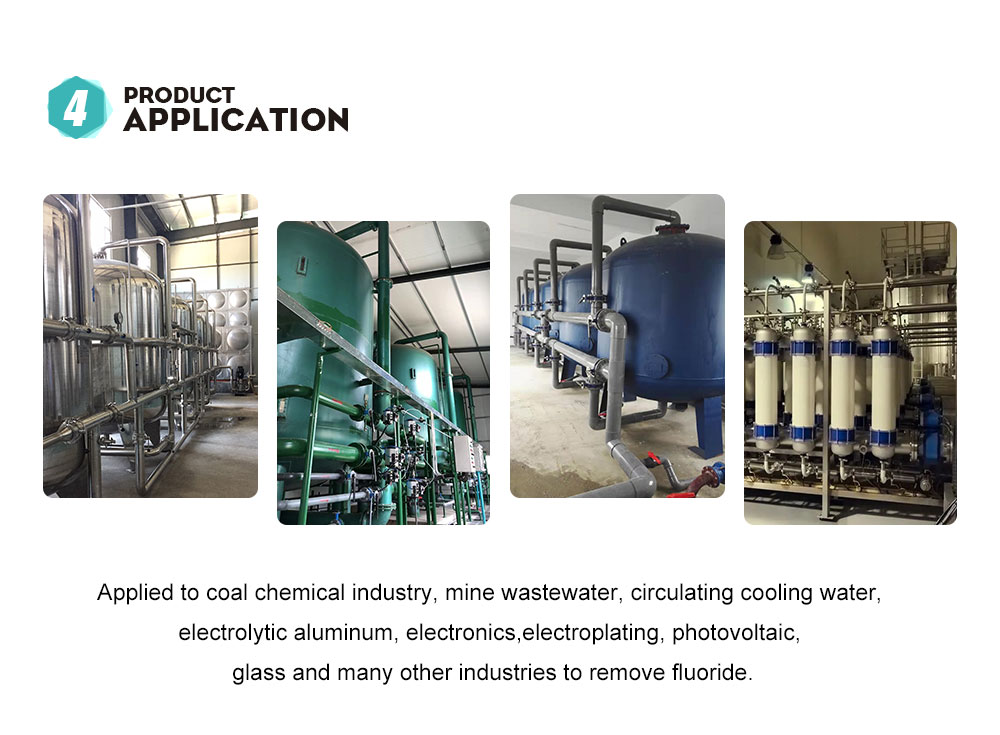

2. Industrial Wastewater Deep Treatment

Widely used in coal chemical, mining, circulating cooling water, electrolytic aluminum, electronics, electroplating, photovoltaic, and glass industries. Notably, it meets the strict fluoride requirements of industrial "zero-discharge" projects (e.g., photovoltaic wastewater), helping enterprises achieve environmental compliance and resource recycling (reclaimed water reuse rate >99%).

VI. ZONE: 23 Years of Expertise in Water Treatment

Founded in 2002, ZONE is a technology-driven leader in China’s water filter media industry, with a reputation for quality and innovation:

- Production Strength: 3 modern production lines, 600-ton monthly capacity, and a 193,680-square-foot manufacturing base—capable of fulfilling large-scale orders efficiently.

- Authoritative Certifications: ISO 9001, NSF, FDA, REACH, SGS, and other international certifications ensure global quality compliance.

- R&D Excellence: Led by CEO Dr. Zhang (former researcher at the China National Ceramic Research Institute), ZONE’s team holds multiple water treatment patents and provides customized solutions based on clients’ raw water quality and purification goals.

Take Action for Safer Water Today

Whether you’re addressing regional drinking water fluoride excess or seeking efficient industrial wastewater treatment, ZONE delivers end-to-end support—from product selection to tailored solutions. Share your raw water parameters and purification requirements, and we’ll design the optimal deep fluoride removal plan for you.