ZONE Large Equipment Filter Media

Update time: 25-04-27 Views: 346

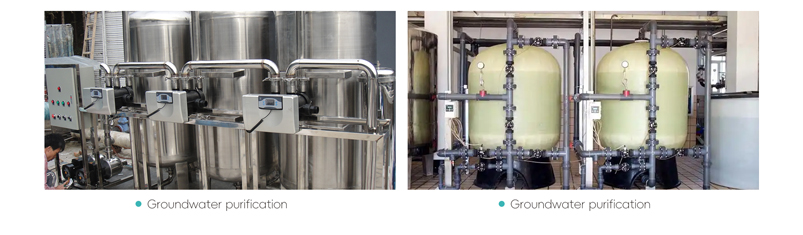

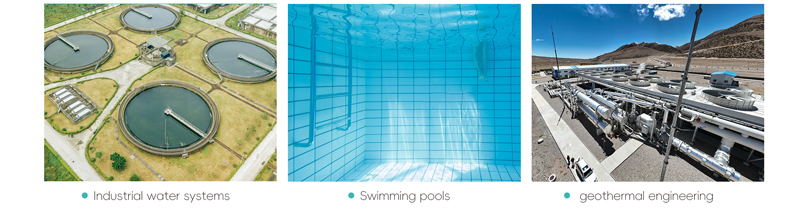

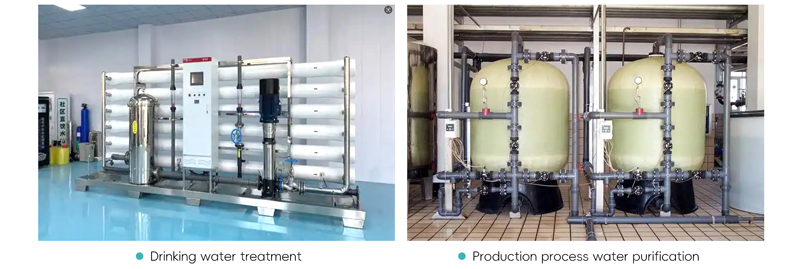

In large-scale water treatment scenarios such as industrial water supply, municipal water systems, and groundwater purification, removing harmful contaminants like heavy metals and fluoride is critical for ensuring water safety. With over two decades of expertise in water purification media, ZONE has developed six high-performance filter media to address diverse water quality challenges, providing precise solutions for complex water bodies. Below is a detailed introduction to these core products and their advantages in heavy metal removal.

1. Activated Glass Filter Media (AGFM): Revolutionizing Filtration Efficiency and Long-Term Contamination Control

Core Advantages:

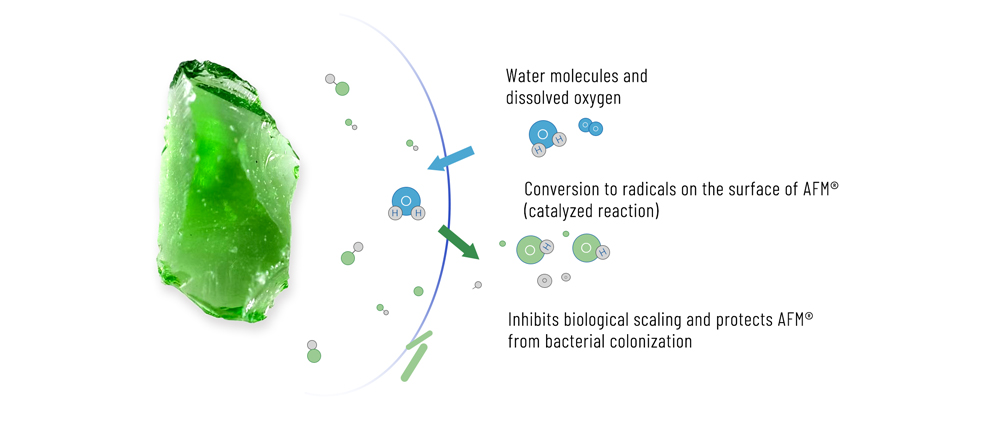

Activated Glass Filter Media (ZONE-AGFM) utilizes microporous slow-release and catalytic reaction technology, boasting a surface area of 50,000㎡ per ton—over 16 times that of quartz sand. This allows it to efficiently adsorb suspended particles (≥1μm), colloids, and heavy metal ions (such as iron, manganese, and copper). Its unique mesoporous structure catalyzes water molecules into free radicals, inhibiting biofilm formation, reducing chemical usage, and lowering operational costs.

Applications:

- Pre-treatment for Reverse osmosis (RO) membranes: Removes suspended solids and heavy metals to extend membrane life and reduce fouling.

- Industrial circulating water systems: Controls scaling and microbial growth to ensure stable equipment operation.

- Municipal water purification: Significantly reduces turbidity and total organic carbon (TOC) for safer water quality.

Performance Data:

Filtration efficiency is 100% higher than traditional sand filters, backwash water consumption is reduced by 50%, and service life exceeds 10 years.

2. Fluoride Removal Particles (ZONE-FR-F02): Dual-Mechanism Solution for Precise Fluoride Removal

Core Technology:

These particles employ a combination of physical adsorption and chemical ion exchange to capture fluoride ions rapidly. Their porous structure first adsorbs fluoride, followed by an ion exchange reaction where OH⁻ on the particle surface replaces fluoride ions, reducing fluoride concentration to below 1.0mg/L (national standard limit). Notably, they also adsorb iron and manganese ions, making them ideal for comprehensive purification of high-fluoride groundwater.

Key Benefits:

- Cost-Effective: Requires only 60% of the loading volume of activated alumina for the same treatment effect, saving equipment investment.

- Robust Adaptability: Operates stably in pH 6.0–8.5, maintaining efficiency even with water quality fluctuations.

- Safe and Environmentally Friendly: No harmful substance leaching, simple regeneration process, and low cost.

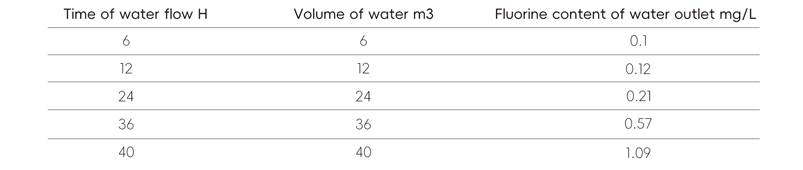

Test Results:

When the raw water fluoride concentration is 5.0mg/L, the treated water fluoride content drops to 0.1mg/L within 6 hours and remains compliant for 40 hours.

3. Iron Removal Particles (ZONE-ZIR-Ar02): Catalytic Oxidation + Deep Filtration for "Yellow Water" Issues

Treatment Principle:

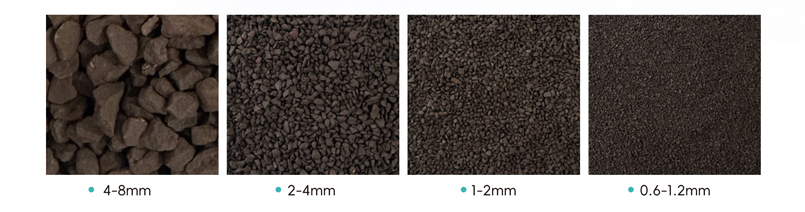

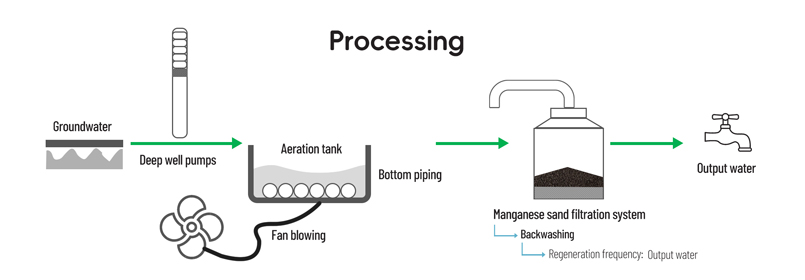

To address the common problem of excessive iron in groundwater, the iron removal particles convert dissolved Fe²+ into insoluble Fe³+ hydroxide through catalytic oxidation, and then achieve deep retention through a layered filtration structure (0.6-4mm particle size gradient). Long-term use can form an iron-based active filter membrane, continuously improving the removal efficiency.

Application Advantages:

- Simplified Process: Efficiently reacts in neutral environments (pH≥7.0) without requiring strong oxidation conditions.

- Versatile Use: Suitable for iron removal in well water, mineral water, and industrial cooling water, with effluent iron ≤0.3mg/L.

- Longevity: Lasts 3–5 years under normal conditions, requiring only regular backwashing for maintenance.

4. Manganese and Iron Removal Particles (ZONE-HMR-Ar02): Synchronous Removal of Dual Heavy Metals for Complex Water Quality

Technical Upgrade:

When iron and manganese ions coexist, traditional media often see reduced efficiency. These particles optimize mineral composition for synergistic catalytic oxidation of Fe²+ and Mn²+, forming an iron-manganese composite active membrane for simultaneous removal. The stratified loading process (coarse particles for adsorption, fine particles for deep filtration) ensures precision, with effluent iron ≤0.3mg/L and manganese ≤0.1mg/L.

Typical Scenarios:

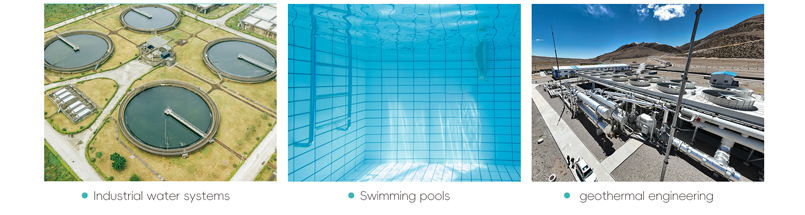

- Geothermal spring water purification: Eliminates color and odor caused by iron/manganese, ensuring water quality.

- Chemical industry circulating water: Prevents equipment corrosion and scaling from iron/manganese ions.

- Rural centralized water supply: Solves regional iron/manganese excess issues in one step.

5. Arsenic Removal Filter Media PRO (ZONE-HMR-AR02): Targeted Adsorption for Highly Toxic Arsenic Pollution

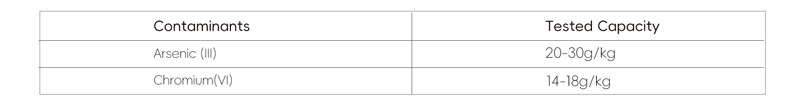

Core Performance:

A "sharp tool" for heavy metal treatment, this media adsorbs 48–60g/kg of pentavalent arsenic (As⁵+) and 20–30g/kg of trivalent arsenic (As³+), along with 14–18g/kg of hexavalent chromium (Cr⁶+). Its lightweight, porous structure increases unit volume adsorption by 30% and reduces equipment footprint by 50%, making it ideal for emergency water supply and deep purification.

Safety Features:

- Food-Grade Material: Certified by the EU, ensuring safety in drinking water treatment.

- Strong Anti-Interference: Maintains ≥95% arsenic removal rate even in high sulfate/carbonate environments.

- Flexible Application: Can be used alone or combined with other media to adapt to different treatment scales.

6. End-to-End Solutions: Integrated Support from R&D to Application

All six ZONE filter media undergo strict water quality compatibility testing and offer customizable formulations (particle size adjustment, composite modification) to meet specific customer needs. We also provide professional process design services:

1. Pretreatment System Design: Optimizes media layers and loading based on water quality analysis.

2. Intelligent Backwash Solutions: Reduces energy and water consumption through flow and pressure differential monitoring.

3. Regeneration Technology Support: Provides efficient regeneration processes for media like iron/manganese and arsenic removal, extending service life.