Filtration principle of porous ceramics

Update time: 22-09-06 Views: 1263

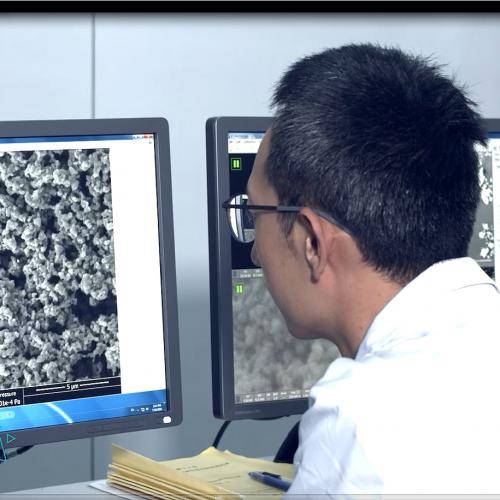

Porous ceramic filtration is a filtration method that combines adsorption, surface filtration and depth filtration. For the filtration and separation of liquid-solid and gas-solid systems, the filtration mechanisms are mainly inertial collision, diffusion and interception. The impurity particles in the fluid flowing through the microporous channels of the porous ceramic filter element are captured by the contact with the microporous channel walls due to inertial action. The inertial impact is proportional to the square of the diameter of the impurity particles and inversely proportional to the flow rate and fluid viscosity. Due to Brownian motion, the impurity particles leave the streamline and come into contact with the wall of the micropore, and are thus captured. The diffusion capture is inversely proportional to the flow rate and fluid viscosity. The impurity particles are captured because they are larger than the microporous channels, which are surface filtration. The retention is only related to the size of the impurity particles, and has nothing to do with the flow rate and fluid viscosity. When the fluid flows through the porous ceramic filter element, the particles larger than the pore size of the filter element are trapped on the surface to form a filter cake layer, and the particles smaller than the pore size of the porous ceramic filter leave the streamline and the micropore wall due to the influence of inertia and Brownian motion. Some particles are trapped on the surface or deposited in the pores of the porous ceramic. Due to the tortuous and tortuous microporous channels of porous ceramics, coupled with the bridging effect formed by the fluid medium on the surface of the porous ceramics and the influence of inertial collision and Brownian motion, its filtration accuracy is much higher than its own pore size. For example, a 10μm pore size porous ceramic filter element, when the filter medium is liquid, its filtration precision is 1μm; when the filter medium is gas, its filtration precision is 0.5μm. After the ceramic filter has been running for a period of time, the filter cake layer on the surface will thicken due to the fact that the internal through holes of the filter element may be blocked by particulate impurities in the fluid medium, resulting in an increase in filtration resistance. When the flow rate is reduced, it can be regenerated by means of gas backflushing, liquid backflushing or gas-liquid shuffling, so that it can basically return to the initial state level.

Ceramic separation membrane is a ceramic filtration and separation material with porous ceramic as carrier and microporous ceramic membrane as filter layer. The cross section is composed of a support layer with a larger micropore diameter and a thicker thickness, an intermediate transition layer with a certain thickness and a three-layer structure of a filter layer with a small micropore diameter and a very thin thickness. Compared with ordinary porous ceramics, the difference is that the asymmetric pore size changes in a gradient. The more cross-section layers, the smoother the micropore gradient changes, and the better the thermal shock resistance of the ceramic separation membrane. By reducing the thickness of the filter layer, the filtration and separation efficiency can reach or exceed the level of the polymer membrane.