Description

Background and Importance

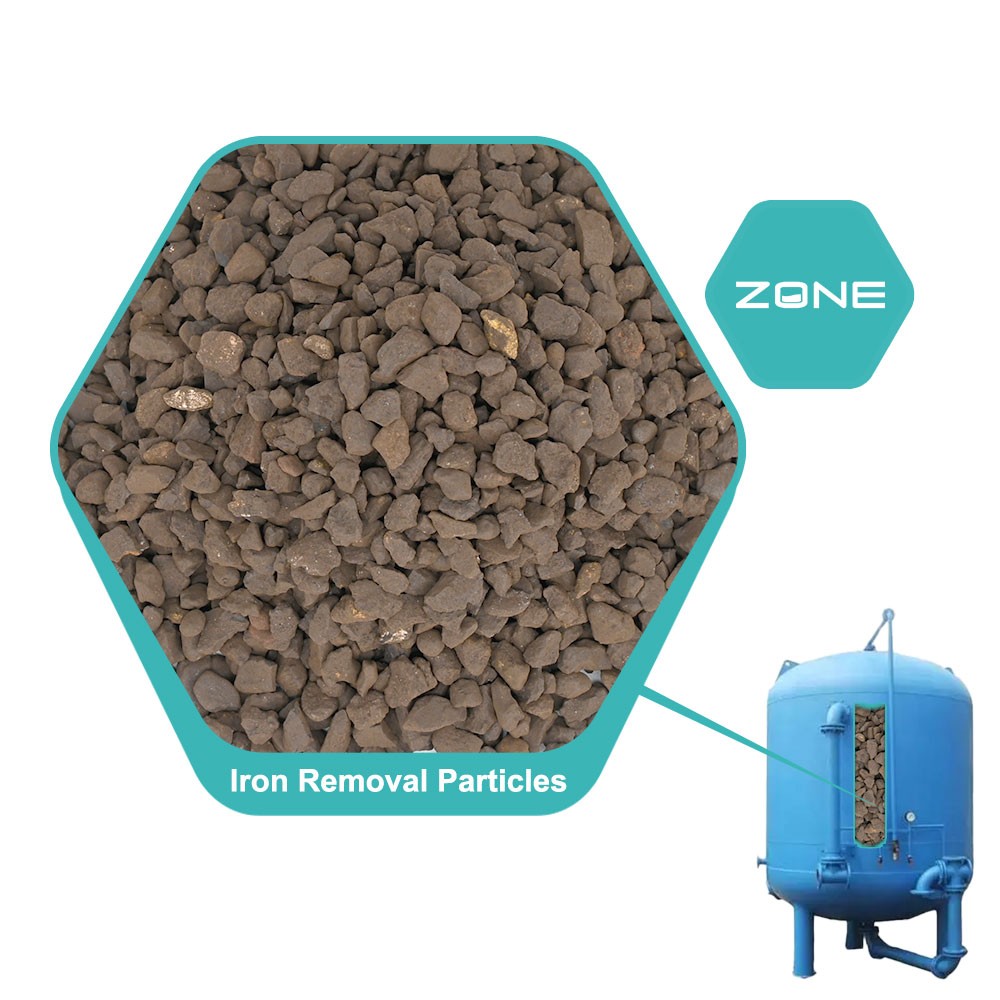

In water resource treatment, excessive iron and manganese in groundwater pose significant risks to water quality safety. High concentrations of these elements not only affect sensory properties (e.g., discoloration, odor) but also harm human health and industrial processes.ZMIR, as a widely used filtration medium, plays a critical role in removing iron and manganese from groundwater. Its scientific application is essential forensuring water safety.

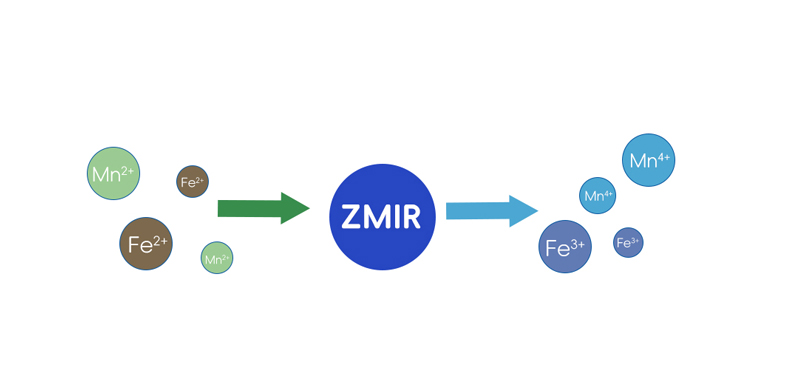

Core Principles of Iron-Manganese Removal:

01.Catalytic Oxidation

ZMIR can catalyze the oxidation of dissolved Fe2+ and Mn2+ into insoluble Fe3+ and Mn4+ hydroxides. These precipitates are subsequently removed via filtration. Studies show this process achieves high efficiency under optimal conditions.

02.Active Filter Membrane Formation

Prolonged use ofZMIR leads to the formation of iron- or manganese-based active filter membranes on its surface, which can significantly improve overall removal performance.

Operational Procedures:

···Pretreatment and Filtration Media Loading

Filter Preparation: Inspect filter tanks to ensure uniform water distribution and clean internal piping systems.

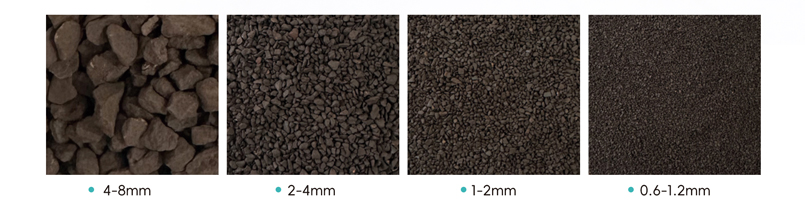

01.Layered Filling Structure:

Top Layer (4–8mm coarse sand/quartz): Intercepts large particles and distributes inflow.

02.Main Filtration Layer (ZMIR):

Top Layer (4–8mm coarse sand/quartz): Intercepts large particles and distributes inflow.

·Upper (2.0–4.0mm): Adsorbs iron oxides and initiates catalytic oxidation.·Middle (1.0-2.0mm): Enhances retention of iron-manganese oxides.

·Lower (0.6–1.2mm): Facilitates deep filtration and active membrane formation.

·Total thickness: 800–1,200mm (extended to >1,200mm for coexisting Fe/Mn).

03.Support Layer

Support Layer (8–32mm gravel/quartz): Prevents media loss and ensures even water distribution.

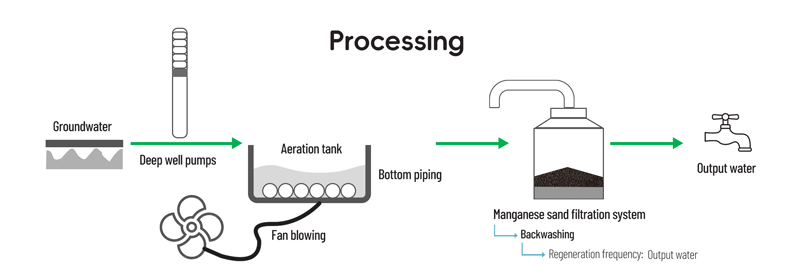

···Aeration and Oxidation

Introduce oxygen via aeration devices to oxidize Fe2+ and Mn2+, improving removal efficiency during

···Filtration Process

Pass iron/manganese-containing groundwater through theZMIR layers. Filtered water meets safety standards, with Fe/Mn concentrations reduced to permissible levelssubsequent filtration.

···Backwashing Maintenance

It can effectively remove the impurities trapped in the manganese sand filter layer, restore the activity of the filter media, and ensure its continuous and stable performance of iron and manganese removal.

···ZMIR Dosage Formula:

It can effectively remove the impurities trapped in the manganese sand filter layer, restore the activity of the filter media, and ensure its continuous and stable performance of iron and manganese removal.

Quantity (tons) = Filter tank radius² × π × Filling height × Bulk density

- Radius (m), Filling height (0.8–1.2m)

- Bulk density:

0.6–1.2mm: 1.7 t/m³

1–2mm: 1.6 t/m³

2–4mm: 1.5 t/m³

·Note: For high Fe/Mn concentrations, reduce filtration speed, extend backwashing cycles, and increase filling height.

·Example

If the radius of the filter tank is 1.5 m, the filling height is 1.2 m, and the capacity of manganese sand is 1.8 t/m³:

Dosage = 1.5² × 3.14 × 1.2 × 1.8 ≈ 15.26 ton、

···The regeneration method of ZMIR includes the following steps

It can effectively remove the impurities trapped in the manganese sand filter layer, restore the activity of the filter media, and ensure its continuous and stable performance of iron and manganese removal.

Quantity (tons) = Filter tank radius² × π × Filling height × Bulk density01.Configuration of regenerant:

Use acidic potassium permanganate to oxidise Mn2O3 in manganese sand to MnO2, so that the ZMIR can restore the adsorption and oxidation capacity of Mn2+ in water. The concentration of regenerant can be configured according to the high or low manganese content of the groundwater, ranging from 0.05% to 10%.

02.Regeneration treatment:

The saturated and passivated manganese sand is regenerated with a powder or liquid agent of acidic potassium permanganate in a configuration. The ZMIR is rinsed by the regeneration agent and then drenched with tap water to be neutral, thus restoring its adsorption and oxidation properties.

03.Recycling regeneration:

Adopting one ZMIR regeneration device can simultaneously meet the filter media regeneration needs of one or more than two iron and manganese removal filters. In order to make the groundwater treatment system operate continuously and stably, several iron and manganese removal filters can be connected in parallel for regeneration treatment.

Please note that the above use and regeneration methods are for reference only, and the specific operation may vary depending on the equipment model, water quality conditions and other factors. In actual application, it is recommended to make comprehensive consideration according to the specific situation and follow the instructions and operating procedures of the relevant equipment.

Key Considerations:

···Water Quality Requirements

Effective in neutral/weakly alkaline environments (pH ≥7.0). Acidic conditions dissolve the particles, rendering it ineffective. Prioritize iron removal before manganese to avoid interference.

···Media Selection and Replacement

ZMIR is suitable for iron removal.

Lifespan: 3–5 years.

Extend usage if active rust-coated particles remain; replace coarsened media if efficiency declines.

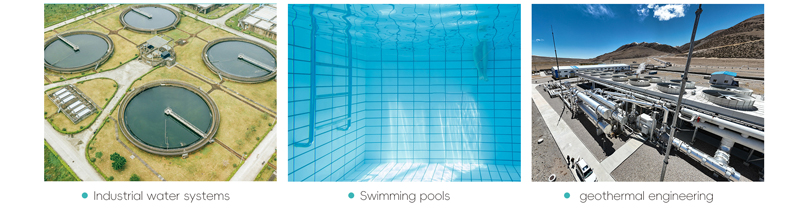

Application:

ZMIR is widely employed in

·Groundwater purification

·Drinking water treatment

·Industrial water systems (power, printing/dyeing, chemical industries)

·Swimming pools and geothermal engineering