Solving the Fluoride Crisis: Next-Generation Mineral Composite Technology for Safe Drinking Water

Update time: 25-11-27 Views: 108

Millions worldwide suffer from health issues caused by excessive fluoride in drinking water. While traditional removal methods struggle with high costs, complex operation, and inconsistent performance, ZONE's breakthrough mineral composite Fluoride Removal particles—developed over 21 years of specialized R&D—offer a game-changing solution. This article explores the fluoride problem, reveals why conventional technologies fall short, and demonstrates how ZONE's dual-reaction mechanism delivers superior, economical, and sustainable results.

1. The Global Fluoride Health Challenge

Fluoride is a double-edged sword. The WHO and China's GB5749-2006 standard cap safe fluoride levels at 1.0 mg/L. Below 0.5 mg/L, dental caries risk rises; above 1.5 mg/L, teeth develop unsightly fluorosis stains. Chronic exposure to water exceeding 2.0 mg/L causes skeletal fluorosis—a debilitating bone disease affecting millions in rural China, India, Africa, and beyond.

In China alone, high-fluoride groundwater plagues the North, Northwest, and Northeast regions, with concentrations 3–10 times over the limit. These waters are typically alkaline and mineral-rich, creating a perfect storm that cripples traditional treatment systems.

2. Why Traditional Fluoride Removal Fails

Current mainstream technologies hit three critical barriers:

Activated Alumina Limitations

As the most common adsorption method, activated alumina works only in narrow acidic conditions (pH 5.5–6.5). Its surface hydroxyl groups are easily disrupted by bicarbonate ions, cutting capacity by 45% or more in typical groundwater. Regeneration is a nightmare—requiring 60x volumes of aluminum sulfate and costly pH readjustment.

Hydroxyapatite Weaknesses

While selective, this media lacks mechanical strength, breaks down in turbulent flow, and costs ¥0.30+ per cubic meter of treated water—prohibitively expensive for large-scale rural supply.

Coagulation-Precipitation Drawbacks

Aluminum salt dosing generates massive fluoride-laden sludge and risks aluminum carryover in finished water, creating secondary contamination concerns.

All three suffer from rapid capacity decay, frequent regeneration, and spiraling operational costs—especially in hard, alkaline groundwater with competing ions.

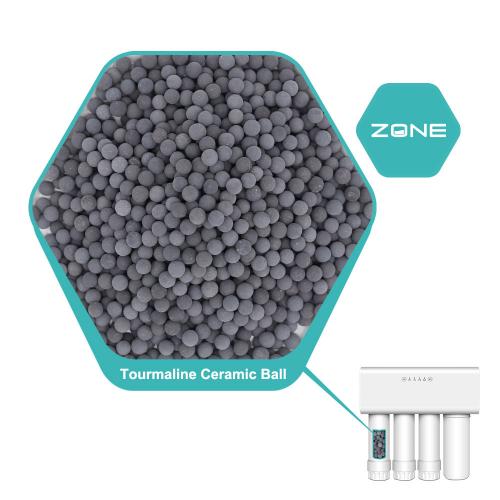

3. ZONE's Mineral Composite Breakthrough

ZONE's R&D team, led by Dr. Zhang (former China National Ceramic Research Institute scientist and National Patent Award winner), leveraged 21 years of water treatment expertise to develop a novel mineral composite fluoride removal material. Already deployed in 3,000+ projects worldwide, this innovation fundamentally rethinks fluoride removal through a dual physical-chemical reaction mechanism.

4. How Dual-Reaction Technology Works

First Reaction: Lightning-Fast Physical Adsorption

Proprietary inner-outer layer pore architecture creates an enormous specific surface area that rapidly traps fluoride ions in micropores within seconds. This 3D interconnected structure slashes hydraulic retention time to one-third of conventional media, shrinking equipment footprint by 40%.

Second Reaction: Selective Ion Exchange Stabilization

Surface-adsorbed fluoride ions displace internal OH⁻ groups, forming permanently stable fluorine compounds. Unlike activated alumina, the material's active sites exhibit exceptional fluoride affinity, resisting interference from bicarbonates, sulfates, and chlorides—even in harsh alkalinity exceeding 200 mg/L.

The result? Complete fluoride removal in a single pass, without pH pretreatment or chemical dosing.

5. Performance That Outperforms: Data-Driven Advantages

Metric

ZONE Particles

Activated Alumina

Hydroxyapatite

Capacity (5 mg/L inlet)

>3,000 m³/ton

~1,800 m³/ton

~2,000 m³/ton

Regeneration Cost

20% of alumina

Baseline

High

pH Range

6.0–9.0

5.5–6.5 only

6.5–7.5

Bicarbonate Resistance

No interference

45%+ capacity loss

20% loss

Iron/Manganese Removal

Yes (40–60%)

No

Minimal

Key Advantages at a Glance:

- 30–40% less media required vs. activated alumina

- ¥0.20–0.30/m³ operating cost through raw/treated water blending

- Safe & stable: No pH adjustment, zero toxic leaching

- Easy regeneration: Ambient-temperature alkali wash; >80% capacity after 5 cycles

- Multi-contaminant removal: Tackles iron and manganese simultaneously

- Extreme durability: Proven in water with 850 mg/L hardness and 320 mg/L alkalinity

6. Real-World Applications & Success Stories

Rural Decentralized Water Supply

In Hebei Province, a 5 m³/h village station achieved 24-month continuous operation with simple farmer-managed maintenance, cutting per-capita water costs by 60%.

Premium mineral water Production

A bottling plant in Yunnan uses ZONE media to selectively remove 4.2 mg/L fluoride while preserving natural calcium and magnesium, protecting brand quality.

Industrial Pre-Treatment

For photovoltaic wastewater (80 mg/L fluoride), ZONE particles reduced loading on RO membranes by 95%, extending membrane life 3× and saving ¥2 million annually in replacement costs.

7. Buyer's Guide: 4 Must-Have Selection Criteria

1. Proven Technical Pedigree

Look for manufacturers with deep R&D roots. ZONE operates a 53,800 ft² production base, holds national-level patents, and has specialized exclusively in filter media for over two decades.

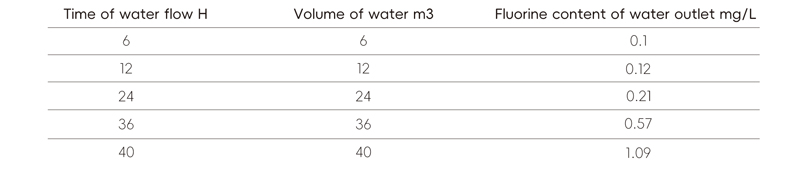

2. Dynamic Pilot Data

Insist on continuous-flow test results, not static lab adsorption. ZONE provides 1 m³/h pilot reports for every project.

3. True Life-Cycle Cost

Calculate: Media price + regeneration chemicals + labor + replacement frequency. ZONE's 5-year TCO is 40% lower than activated alumina.

4. End-to-End Service

True partners offer free raw water analysis, custom system design, and on-site regeneration training—standard with every ZONE deployment.

From the labs of China's Ceramic Research Institute to thousands of villages worldwide, ZONE's fluoride removal particles embody a simple philosophy: advanced technology should deliver simple, reliable results. By eliminating pH adjustment, reducing sludge, and cutting costs, we've made safe drinking water accessible where traditional methods failed.

As a hidden champion in water treatment media, ZONE continues to pioneer mineral material modification. Facing a fluoride challenge? Send us your water report—we guarantee an optimal solution.